Airport windsocks are simple and unassuming elements of an airport runway. While they may be basic, they are essential in the operations of large airports or small airfields.

Despite the latest technological innovations in the aviation industry, airports must use windsocks and other simple navigational aids.

After all, windsocks provide pilots with a quick visual indication of wind direction. They are one of the essential airport components that pilots look at during the critical phases of landing and takeoff operations.

- What Are Airport Windsocks

- How Windsocks Work

- Benefits for Pilots

- Types of Windsocks

- Maintaining Your Windsocks

What Are Airport Windsocks

A windsock is a tapered cloth tube with a narrow and conical shape. Both of its ends are open, and it looks like a giant sock, hence the name. Meanwhile, the striped version of windsocks is called wind cones since they are similar to traffic cones.

Before windsocks were employed in airports to determine wind speed and direction, they had a different function centuries ago. In 150 A.D., windsocks were used by the Romans as banners to represent their army. On the other side, the Japanese utilized windsocks, also known as “koinobori,” to honor men during the Boys’ Day festival. Currently, the Japanese still use koinobori as decorations to celebrate Children’s Day every 5th of May.

Why Are They Important

Pilots often use windsocks as a quick, visible reference that helps them determine wind direction and wind speed.

Most airport windsocks are made from vinyl fabric, a light and durable material that can withstand strong winds and other elements. Lights can be attached to the top or on the inside so that they can be observed during nighttime and harsh weather conditions.

How Windsocks Work

Airport windsocks can measure the wind speed and direction by letting wind enter from one end and out of the other. Pilots can estimate the wind speed by the intensity of the sock’s movement.

The stripes over the sock are equal to a specific speed. For example, if the first stripe from the pole is parallel to the ground, the wind is at least 3 knots or 3.5 miles per hour (mph). If the entire sock is parallel to the ground, the wind speed is higher than 15 knots or 17 mph.

Meanwhile, the windsock’s end further to the pole indicates the direction of the wind. You can check out the Airport Wind Cone Specifications in the U.S. for more information on how windsocks work.

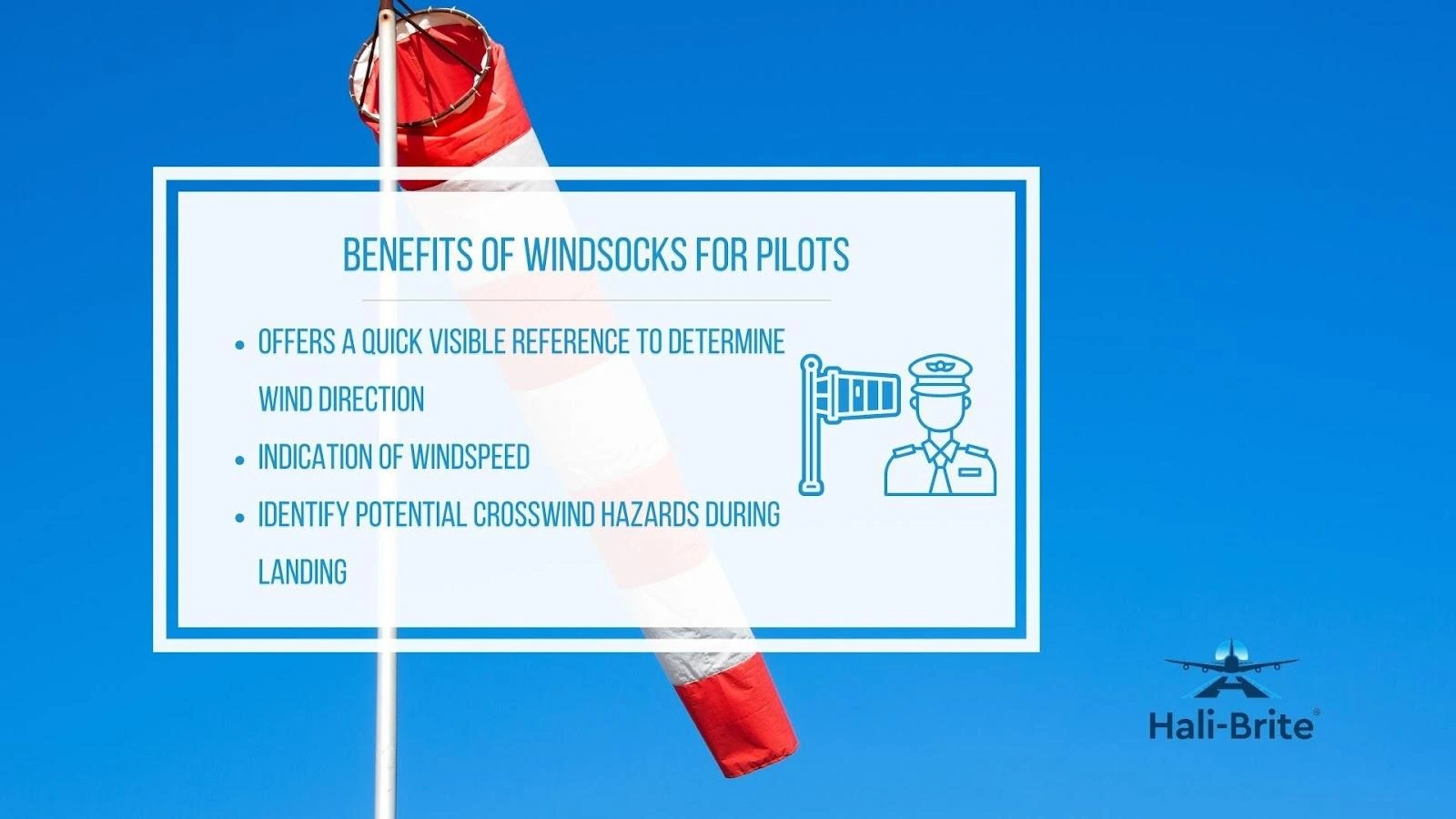

Benefits for Pilots

Pilots use windsocks to tell wind direction and speed while performing takeoff or landing maneuvers. While some airports use broadcast weather covering wind speed and direction, pilots often look into windsocks to verify this information.

Types of Windsocks

Airport windsocks are classified based on their manufacturing styles and applications. However, they often are mounted on a pole where the windsock can rotate and change direction freely based on the air.

Cotton and synthetic materials like nylon and polyester are the most common materials used for windsocks. They can have red, yellow, white, green, orange, or a combination of these colors. Below are some of the common types of windsocks in the aviation industry.

Swivel Arm Windsock

This type of windsock has a bearing housing and arm attached to it. The windsock is fitted with a harness for it to move freely. Meanwhile, one of the ends is connected to a mouth ring, and the other is connected to a snap clip or swivel shackle.

Pivoted Frame Windsock

Pivoted frame windsock has a frame where multiple rings are joined together. Some iterations of this windsock only use a single ring where the sock is fitted in a small slot. The larger end of the windsock is then tied with cables or lace cords to the frame and secured in place.

According to the Federal Aviation Agency (FAA), an aviation windsock must be able to orient itself against winds of at least 3 knots or 3.5 miles mph. It should also be able to extend to winds of 15 knots or 17 mph fully. The agency also has several guidelines about the cone assembly type, fabric, size, and style.

Most airport windsock sizes fit into these specifications:

- Eight Feet Long Windsocks With 18-Inch Throw Opening

- Twelve Feet Long Windsocks With 36-Inch Throw Opening

Maintaining Your Windsocks

1. Keep It Away From Any Rough Surface

Place your windsock in an area that won’t touch roofs, building walls, bushes, branches, and other objects that can damage it.

2. Always Examine for Damage

Windsocks are exposed to the elements, such as the sun, damaging them and making their colors fade over time. Always check for small rips, holes, and tears and repair them as soon as possible.

3. Don’t Forget to Wash Your Windsocks

Clean your windsocks regularly to remove dust, pollutants, and other particles that can cause the fabric to degrade. Never use a washer to clean it, and use a mild detergent. Moreover, don’t fold the windsock and let it dry before storing it.

Get Quality Windsocks With Hali-Brite

Windsocks are still an essential part of any airport. It’s one of the best ways pilots can get real-time information about wind speed and direction.

Hali-Brite offers various types of windsocks compliant with the FAA and ICAO guidelines. Our airport windsocks are made from high-quality materials meant to last long. If you want to receive a quote, contact us today.

Visit Hali-Brite’s Blog to get some of the latest stories about the aviation industry.